The importance of monitoring gases in the winemaking process

Winemaking is an age-old art that requires precise attention to every detail of the process, from the growing of the grapes to the bottling of the finished wine. Among the many elements to be monitored, the gaseous composition of the environment is crucial to the development and quality of the wine. Oxygen (O2) and carbon dioxide (CO2) are two particularly important gases to monitor.

The winemaking process is a meticulous process characterised by a series of complex and interdependent stages, where the slightest variations can profoundly influence the final product. Throughout this process, gases such as oxygen and carbon dioxide are naturally generated and play an essential role in the chemical reactions that define the aroma, flavour and overall quality of the wine.

Monitoring the concentrations of these gases at different stages of winemaking is therefore essential for ensuring both the quality of the final product and the safety of winery personnel. By utilizing gas sensors, winemakers can precisely regulate and optimize gas levels, mitigating the risk of off-flavors or safety hazards. This meticulous control not only preserves the integrity and complexity of the wine but also enhances the overall efficiency and reliability of the winemaking process. Ultimately, it underscores the importance of integrating advanced technologies to uphold the standards of excellence and safety in the dynamic world of winemaking.

APPLICATION

Stages of winemaking

Fermentation

During primary fermentation, yeasts consume sugars and produce alcohol and carbon dioxide as byproducts. Monitoring the CO2 levels during this phase is essential to ensure that the fermentation process is proceeding as expected. Elevated CO2 levels can indicate a healthy fermentation, while a sudden drop could signal a problem. However, it’s crucial to note that excessive CO2 levels in confined spaces can pose a significant risk to the health of winery workers.

Maturation

In this stage, the wine is often stored in tanks or barrels. Proper oxygen management is crucial. Too much oxygen exposure can lead to oxidation, negatively affecting the wine’s flavor and color. Conversely, too little oxygen can result in reduced development of desirable aromas and flavors. Additionally, workers must be aware of the potential hazards of working in confined spaces with reduced oxygen levels.

Bottling

Oxygen levels must be carefully controlled when bottling wine to avoid unwanted oxidation. Winemakers use inert gases, such as nitrogen or argon, to displace oxygen in the bottle before closing it with a cork or screw cap.

PRODUCTS

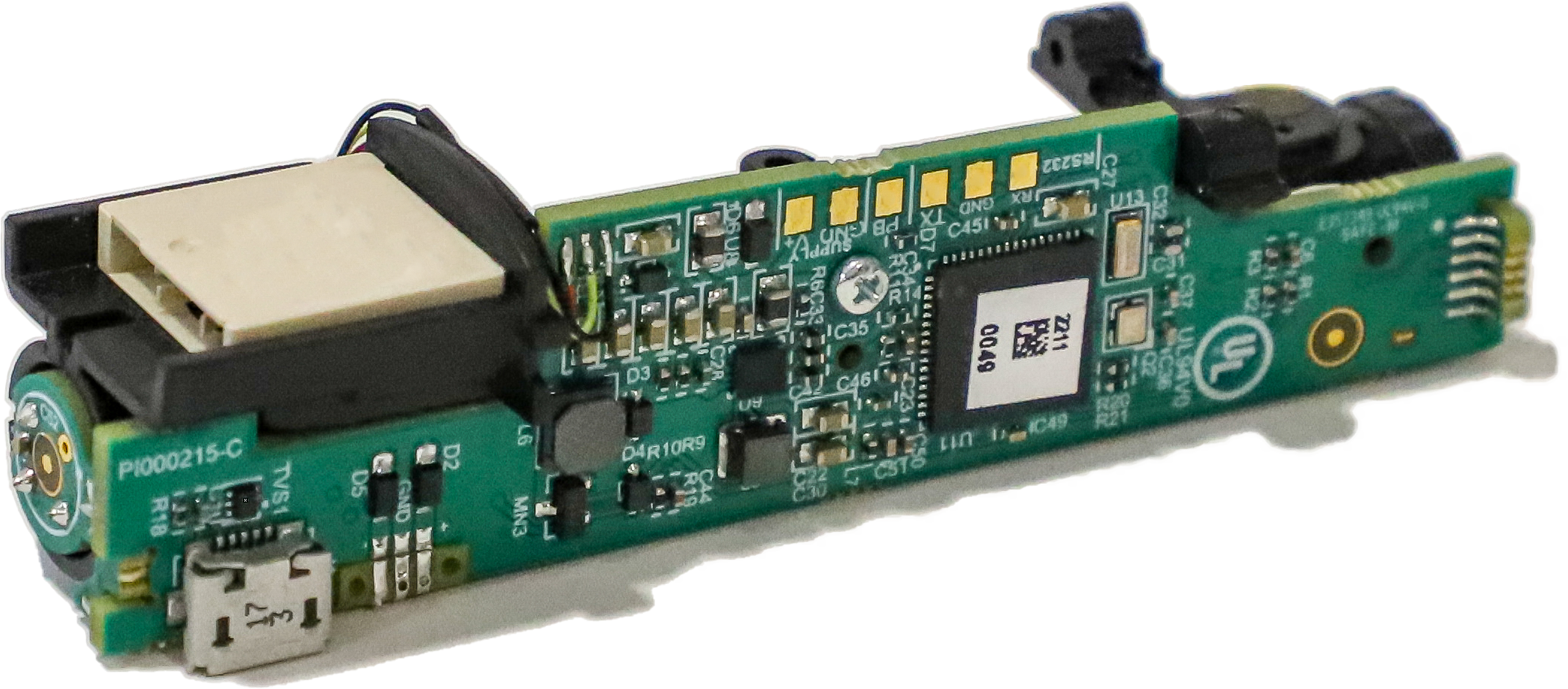

O2 gas analyzer

- Measuring range: 0-100%

- Accuracy: ±0.02% O2 at 1%